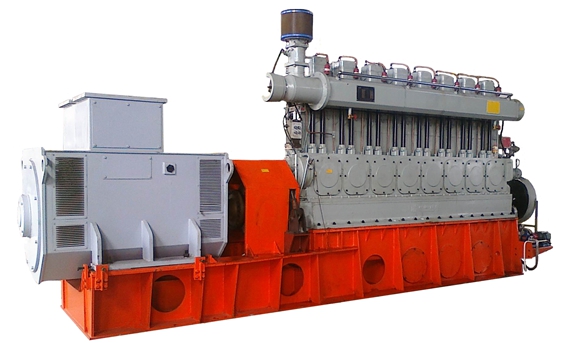

高分子脫硝設備進行了模塊化設計,利于現場快速安裝,該系統主要包括:上料系統、輸送系統、下料器系統、噴射系統、控制系統。

The polymer denitration equipment is modularized to facilitate the rapid installation on site. The system mainly includes: feeding system, conveying system, feeder system, injection system and control system.

在垃圾焚燒爐標高24.7m前墻設置2支噴槍,左右墻標高24.7m各設置1支噴槍,左右墻標高25.9m各設置1支噴槍,單爐共設置6支脫硝噴槍。噴槍采用分層分區域布置,對煙氣進行優覆蓋,使得氮氧化物達到很好的脫除效率。

Two spray guns are set on the front wall of the waste incinerator with an elevation of 24.7m, one spray gun is set on the left and right walls with an elevation of 24.7m, one spray gun is set on the left and right walls with an elevation of 25.9m, and a total of 6 denitration spray guns are set on a single furnace. The spray gun is arranged in layers and regions to cover the flue gas optimally, so as to achieve good removal efficiency of nitrogen oxides.

1負壓上料系統

1 negative pressure feeding system

負壓上料裝置輸送的方式是由操作人員通過負壓管從料包中將脫硝藥劑吸入料倉內,很大程度地節省了人員的操作時間及勞動強度,節約了人工成本。

The conveying mode of the negative pressure feeding device is that the operator sucks the denitration agent from the material bag into the silo through the negative pressure pipe, which greatly saves the operation time and labor intensity of the personnel and saves the labor cost.

2輸送系統

2 conveying system

羅茨風機是整個輸送系統主要的組件之一,它為整個系統提供足夠的風量及風壓,根據運行情況變頻調整。

Roots blower is one of the main components of the whole conveying system. It provides sufficient air volume and air pressure for the whole system and can be adjusted by frequency conversion according to the operation.

3下料器系統

3. Feeder system

卸料器由驅動電機采用變頻控制,以適應鍋爐工況的調節,具有運行穩定、抗壓性能好、耐磨損的特點,同時與垃圾焚燒爐在線數據連接,做到實時跟蹤調整,節約脫硝劑成本。

The discharger adopts frequency conversion control by the driving motor to adapt to the adjustment of boiler working conditions. It has the characteristics of stable operation, good compressive performance and wear resistance. At the same time, it is connected with the online data of waste incinerator to achieve real-time tracking and adjustment and save the cost of denitration agent.

4干法脫硝噴射系統

4 dry denitration injection system

干法脫硝噴射系統主要由噴槍及其附件組成,通過調節下料器的變頻器頻率控制脫硝劑輸送量。輸送管與球形分配器連接,球形分配器出口管通過金屬軟管連接噴槍。噴槍采用耐磨損、耐熱變形、耐高溫、耐腐蝕且容易維護的材料;霧化效果及覆蓋面積經過流場模擬和數值計算。

The dry denitration injection system is mainly composed of spray gun and its accessories. The conveying amount of denitration agent is controlled by adjusting the frequency converter of the feeder. The conveying pipe is connected with the spherical distributor, and the outlet pipe of the spherical distributor is connected with the spray gun through a metal hose. The spray gun is made of wear-resistant, heat-resistant deformation, high temperature resistant, corrosion-resistant and easy to maintain materials; The atomization effect and coverage area are simulated by flow field and numerical calculation.

5控制系統

5 control system

采用的為PLC自動化控制,根據鍋爐煙氣在線實時數據反饋對加料量進行PID自動控制,實現干法脫硝系統的自動化控制。

The PLC automatic control is adopted. According to the online real-time data feedback of boiler flue gas, the PID automatic control is carried out for the feeding amount to realize the automatic control of dry denitration system.

The above is the detailed introduction of dry desulfurization, which I hope will be helpful to you If you have any questions, please contact us We will provide you with professional service http://usacato.cn